Boiler Power series 150-1500 kW

The boiler is produced in accordance with European Standards EN13445, EVS-EN 12953-1-8:2002, directive 97/23 CE.

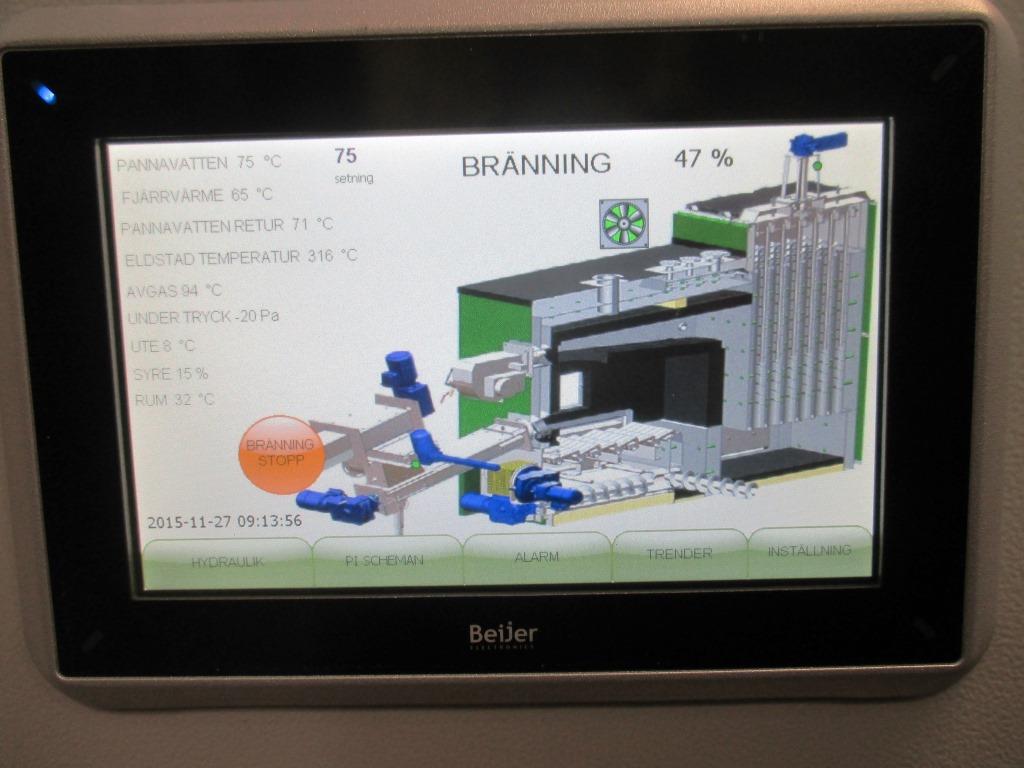

The current boiler has combined combustion zone and convective part. Combustion chamber is of a large volume, which allows to achieve proper combustion. Combustion zone is covered with heat-resistant concrete, the ceiling is covered with concrete vaults, through which air is supplied into secondary combustion zone. Convevtive part of the boiler has single-pass heat exchanger.

All steel, used in the boiler, is of P265GH – P355GH type. Combustion in the boiler takes place on the grate. Material of the grate bars – cast iron containing chrome 20%.

Convective part of the boiler is equipped with flow energizer system – turbulaters. The current system performs two functions: it increases heat exchange due to the increase of flue gas movement and it cleans boiler. Turbulaters move periodically and clean tubes mechanically. Turbulaters are actuated automatically with the help of mechanic drive.

Boiler does not need additional cleaning along the whole heating season. It is necessary to audit the system once a year, which is usually done in summer period together with preventive maintenance.

Main characteristics of the boiler Power series:

- Boiler efficiency reaches up to 95%

- Output range 10-110% from nominal

- Possibility to use fuel, humidity from 10 up to 55%

- Moving grate bar

- Grate bars containing chrome 20%

- Automatic air supply under grate bars and through concrete vaults of the burner

- Vertical single-pass heat exchanger

- Combustion chamber is covered with heat-resistant concrete (in case of fuel, humidity 10-30%, concrete is partially removed, in order to decrease the temperature)

- Combustion chamber with water cooling