Fuel Storage

Amongst the range of products by Bio Mobitek, you will find equipment for storage, feeders for bulk materials, conveyors, and technologic operational equipment, which is necessary for operation of energy and industrial enterprise. In accordance with the necessity, integrated solutions contain equipment for transportation and loading, fuel and ash, mixing, screening, and crushing solution, and, if necessary, there is a possibility to install cooling and heating equipment. We also offer maintenance service along the whole service life of the equipment. Amongst the range of products, minimum operational and maintenance costs are combined with small maintenance demand and work safety.

Moving floor with central beam. The current moving floor is unique and it can have different length

from 3 up to 12 meters. Number of lines is chosen, depending on the required volume. Distinctive part — replaceable knives, which can be replaced, in case of their damages (for example, by tractor when loading fuel). Allowed fuel load onto the current moving floor, height not more than 3 meters or 1000 kg / per square meter.

Moving floor with two beams. It is a welded construction. Number of lines and their length depends on the required

volume. Allowed fuel load per square meter of the floor is 1500 kg. Storage with horisontal floor conveyor, average storage height of bulk material is 3 — 4 meters. In order to fill storage, truck, loader, or front-end loader is used. Storage can be filled from different storage sides, from above or from aside. Advantages — greater productivity and safety.

Spring ejector. Storage system for small output uses spring pressure.

It is a rotating disk with blades of spring steel.

When rotating, fuel gets into screw conveyor and is supplied into the combustion zone of the combustor. It is possible to produce storage with two dimensions – 3 х 3 m and 4 х 4 m. Loading storage – not higher than 5 meters in height and, correspondingly, storage volume – 3 х 3 meters — 45 m3 and storage volume 4 х 4 m3 – 80 m3. The current system can be mounted in the container or into the available building. It is most frequently used in systems up to 750 kW. Advantages of the current storage type – price and simplicity.

When rotating, fuel gets into screw conveyor and is supplied into the combustion zone of the combustor. It is possible to produce storage with two dimensions – 3 х 3 m and 4 х 4 m. Loading storage – not higher than 5 meters in height and, correspondingly, storage volume – 3 х 3 meters — 45 m3 and storage volume 4 х 4 m3 – 80 m3. The current system can be mounted in the container or into the available building. It is most frequently used in systems up to 750 kW. Advantages of the current storage type – price and simplicity.

Keith Walking Floor. Unique moving floor system has been developed and patented in USA.

The main office and production of hydraulic systems are also located in USA. Enterprise has several representatives along the whole world. Bio Mobitek is the representative of KEITH® WALKING FLOOR® in Scandinavian and Baltic countries. Reliable and safe transportation systems can transport loads of unlimited weight and volume. It is safe to move along the system and it can hold up weight of another equipment. All systems are made to order and each one has an individual specification. Systems are energy-saving, they do not need much energy during operation process. It is possible to change width from 1 to 20 m and length – from 2 to 30 m.

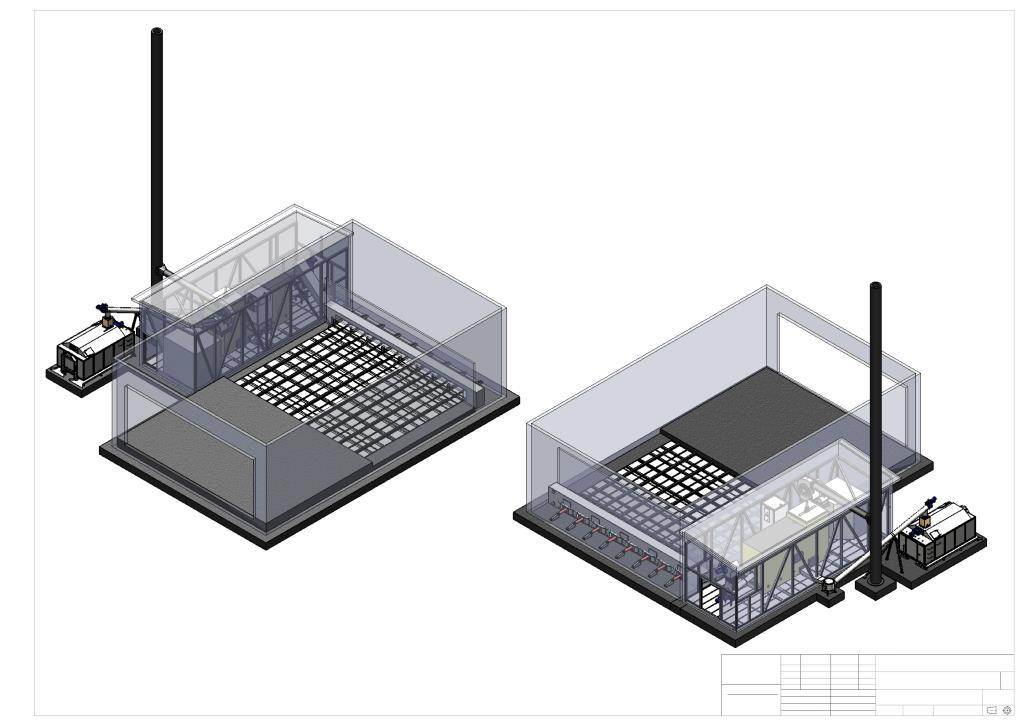

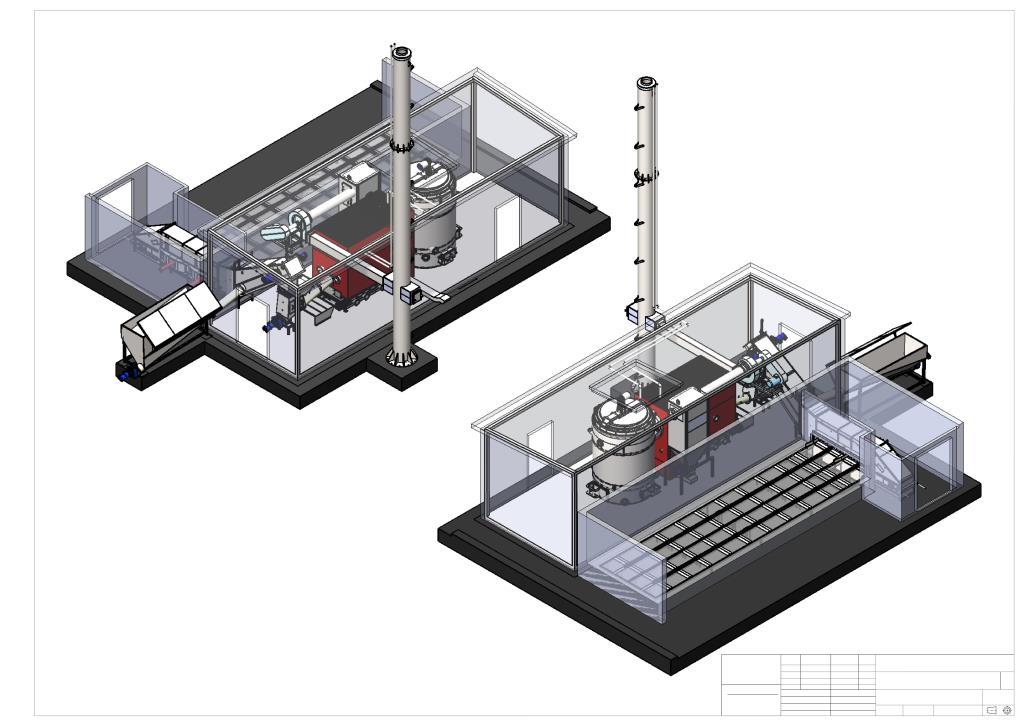

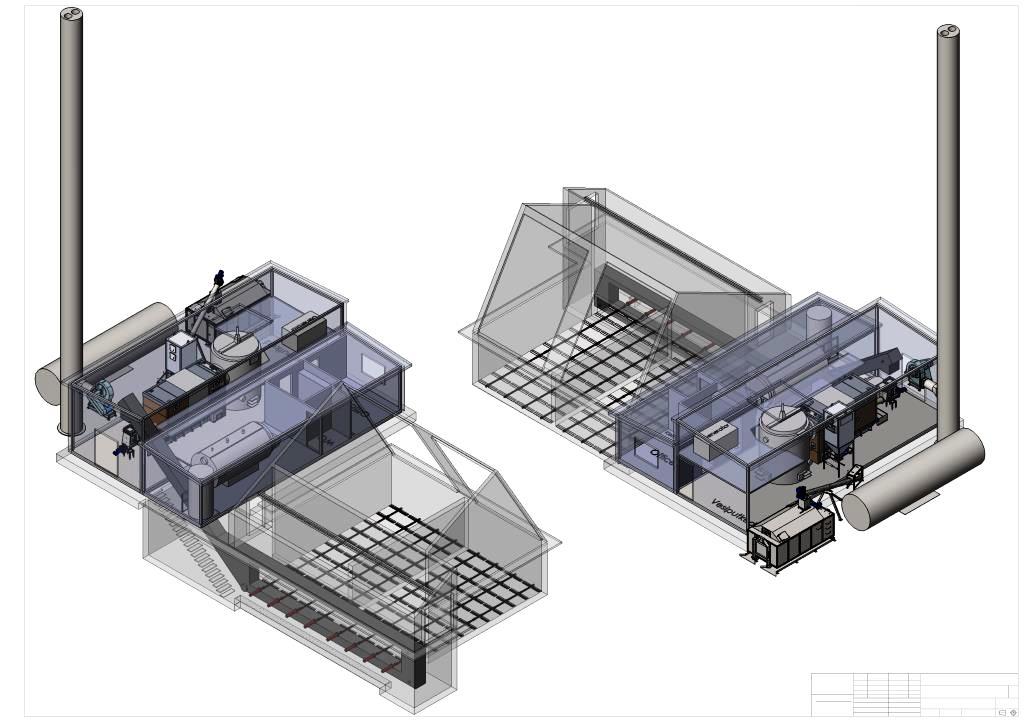

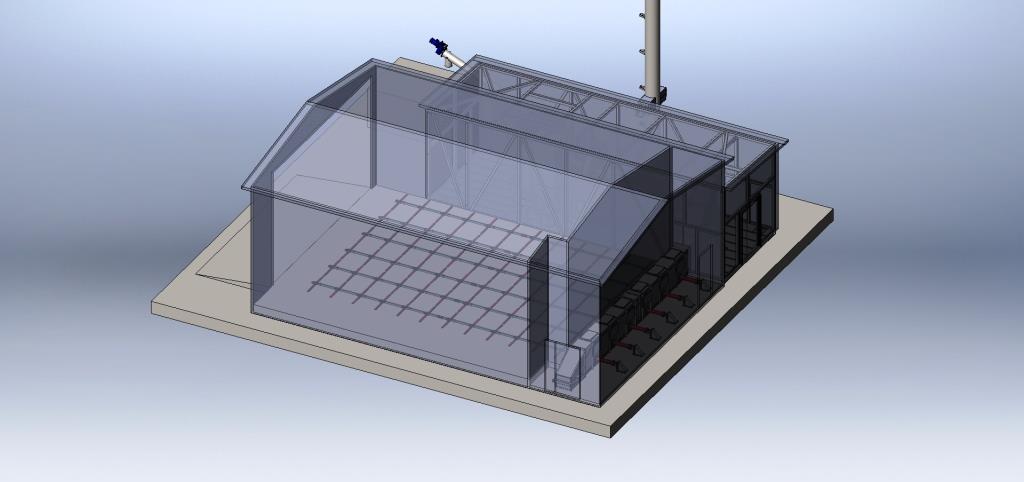

e room is designed depending on storage mechanism, loading type, storage volume, construction possibilities and wishes of the client. Here are possible options of storages:

- Option 1 – container or construction on site. Building is low and has a lifting roof, which allows truck to enter through the gates and unload fuel by lifting body.

- Option 2 – container or building with lifting roof. Fuel is filled through side wall by tractor, loader or truck with help of deck or without it.

- Option 3 – high building, transport gets inside through the gates. The building can have 1 — 10 entrances. Height of the building and gates depends on transport. Bio Mobitek does not recommend to drive heavy vehicles along moving floor elements; in order to unload fuel, enterprise recommends to use tractor or front-end loader.

- Option 4 – a budget construction option. Front-end loader is required. Fuel loading takes place through side opening in a wall. The building can be made of stone, wood, or metal construction. Moving floor is mounted onto concrete foundation. Storage volume is limited.

- Option 5 – storage with moving floors, extended underground. This storage has a large fuel volume. It does not require additional tractor or loader. Fuel is unloaded, practically, from any vehicle. A small construction part is above the level of ground, but most of concrete works are performed below the ground level.

- Option 6 – Storage with spring ejector. Front-end loader is necessary. It can be executed as a module or built in an available building. It is most frequently used in boiler installations of low output.

- Option 7 – Storage with WalkingFloor moving floor. Surface of the storage can hold transport of any weight. Practically no fuel is left on the surface of the storage, which allows to get in without any problem. Surface is smooth and even, damage from tires is not possible. Sections are designed so that they should hold fuel, which is unloaded from trucks. Number of sections is not practically limited. There is no need in additional transport to move fuel.

|

|