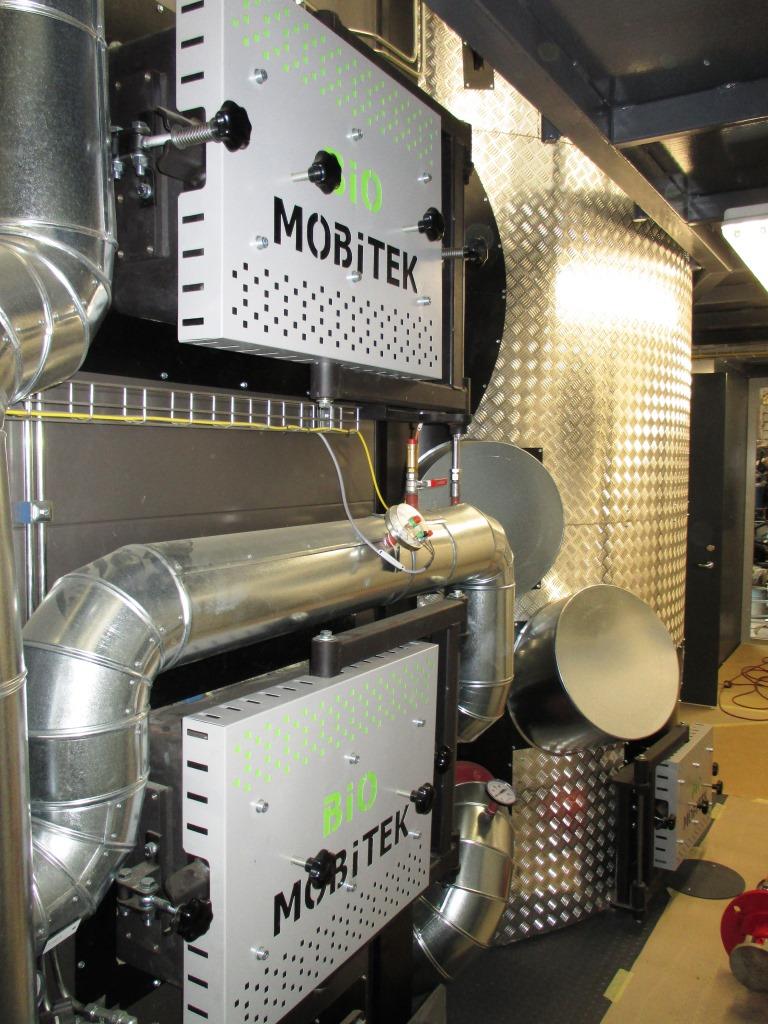

Burner BM series 999 kW — 6 MW

All Bio Mobitek burners are produced in accordance with European Standards EN13445, EVS-EN 12953-1-8:2002, directive 97/23 CE

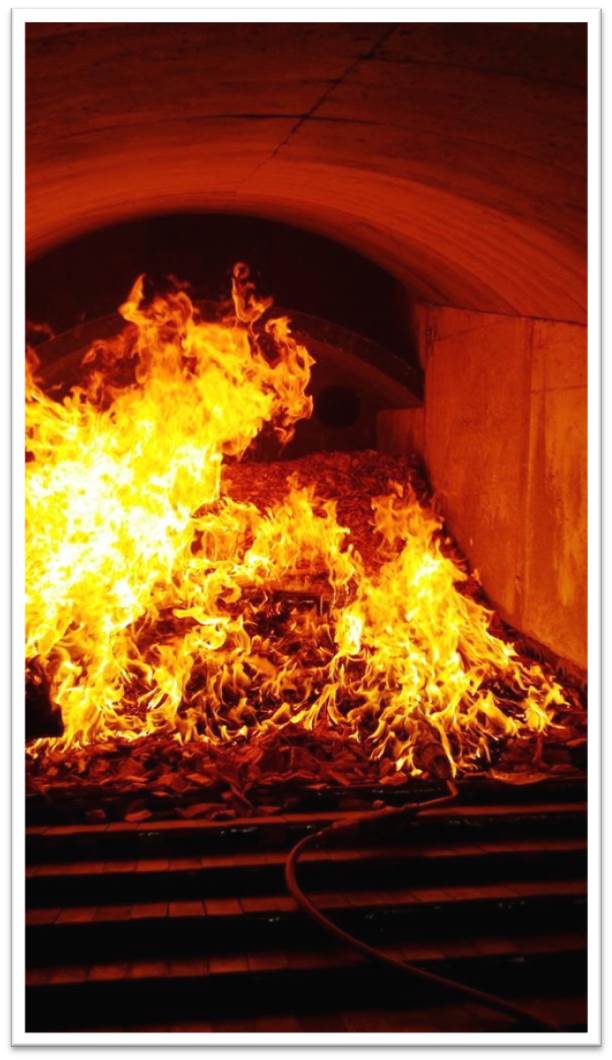

The main element of the burner — steel body with water cooling. The body is made of steel sheets, between which water is circulating. Burner has two side hatches, which are meant for maintenance. Walls of the burner are lined with heat-resistance concrete. Ceiling of the burner is protected with concrete vaults, through which air is supplied. Vaults help to concentrate thermal radiation on fuel and dry it quickly. There is a second vault in front of a central part, above which the combustion chamber is located; air is supplied into the chamber. In afterburner, there are terms for final oxidation of all combustion products. The body is isolated with RUUKKI sandwich panels (width 100 mm) from the outside. Panels are filled with rock wool and are of EI90 fire safety class.

Combustion is completely controlled by automation. Air, at different levels, is supplied from fans through steel air ducts into the combustor. The amount of supplied air is controlled by valves, which are mounted into air ducts. Automatic control system controls the operation of valves. Boiler room is equipped with fans, which remove hot air from the boiler room.

Bio Mobitek ensures normal operation of the burner within 24 months after its commissioning, in case of compliance with operating rules. Body of the boiler and water circuit strapping have a guarantee for 5 years! Manufacturer is entitled to control the compliance with operating rules during the guarantee period. Guarantee is not provided to wearing details. In case of non-compliance with operating rules, manufacturer of the equipment is entitled to decrease or cancel fixed guarantee period.

Main characteristics of the boiler BM series:

- Burner efficiency reaches up to 95%

- Output range 10-110% from nominal

- Possibility to use fuel, humidity from 10 up to 30% and from 30 up to 55%

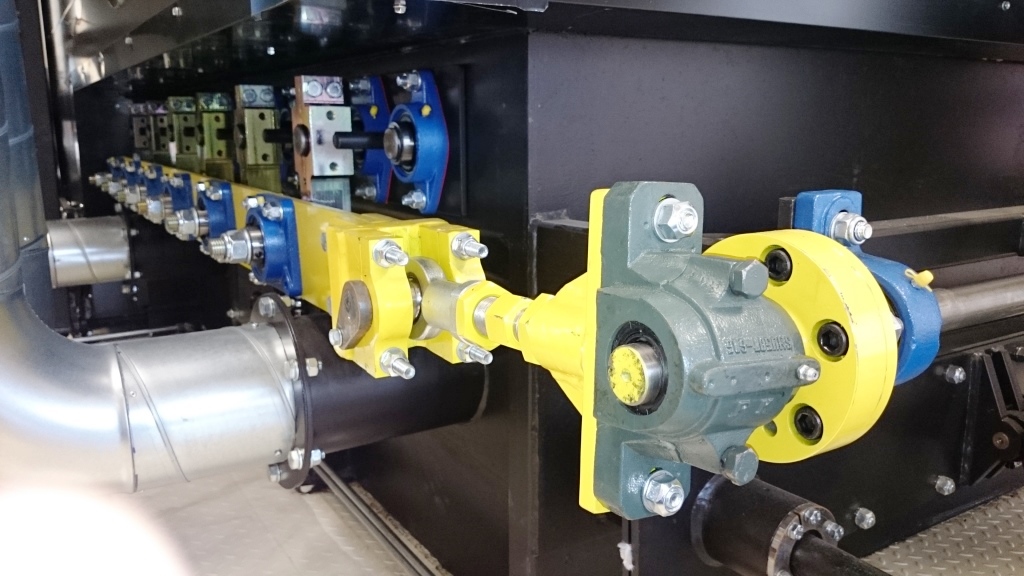

- Moving grate and automatic ash removal

- Grate bar containing chrome Cr 20%

- Automatic air supply under the grate bar and through the concrete vaults of the burner

- Combustion chamber is lined with heat-resistant concrete (in case of fuel, humidity 10-30%, concrete is partially deleted in order to decrease temperature)

- Combustion chamber with water cooling

- Service life not less than 10 years