PowerCont 150-999 kW

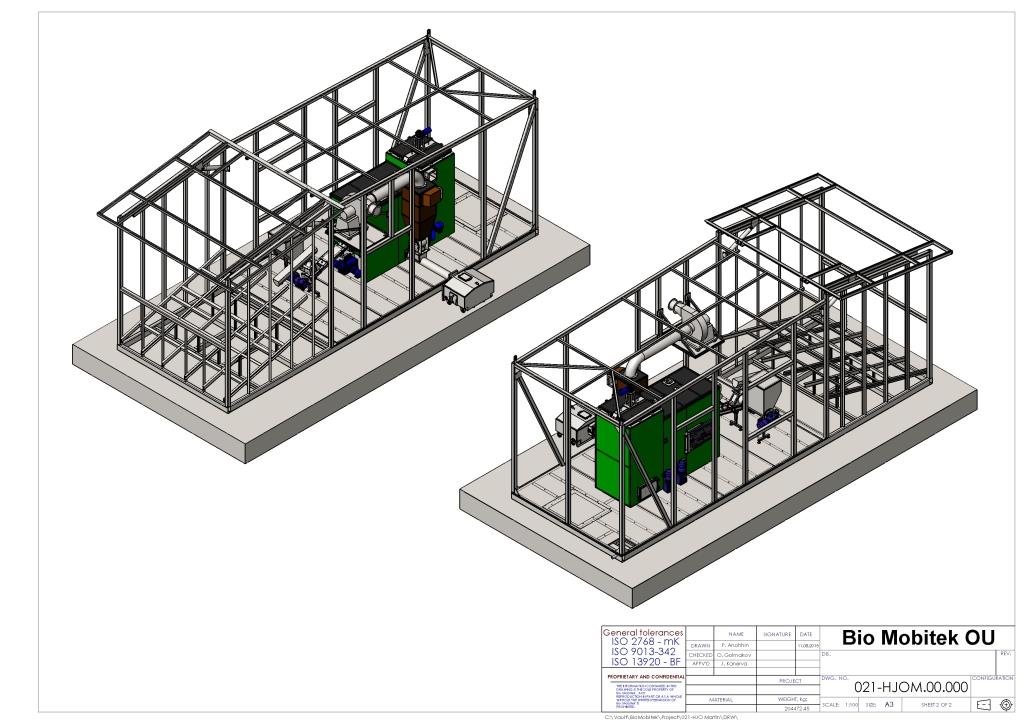

PowerCont modular boiler rooms 150 kW -999 kW

Ideal solution for heating and hot water in private housing and small business. Our clients of the current line are farmers with small production. Price distinguishes the current series.

PowerCont boiler room 150 kW up to 999 kW includes boiler room and fuel storage, volume 25 — 65 m3. The system is ready for test launches after 3 days from the delivery. Bio Mobitek modular boiler systems are meant for heating and hot water in private housing, public and industrial buildings. Boiler installations are highly automated and controlled without the presence of personnel. Presence is necessary only in case of periodic inspection.

Wood chips, granules, sod or milled peat, agricultural and wood processing waste can be used as fuel. Bio Mobitek boiler systems can operate at range 10-110 % from nominal output and with fuel, humidity level 10-55%. Efficiency of such system reaches up to 97%!

- Boiler room module

- Vertical water heating boiler, BM-150…BM-999 series

- Surge bunker with screw fuel supply into the combustion zone

- GSM remote control

- Automatic system of air supply into the combustion zone

- Cyclone with rotary shutter

- Automatic ash removal system from burner and cyclone

- Exhauster

- Water circuit strapping with all necessary circulation pumps and shut-off valve

- Boiler room control system (computer equipment, software)

- Automatic combustion system with fixed settings in order to use different fuel types

- Automatic pressure reset system in boiler

- Ventilation system

- Electric and automation cabinet

- Fuel storage with spring ejector, dimension 3 х 3 meters or 4 х 4 meters.

- Boiler hydraulic station

- Module lighting

- External lighting with movement indicator

- Water collection and drainage system

- Drainage system inside the module

- Decorative interior and exterior trim

Module can be completed with additional units:

- Multi-cyclone (change of cyclone of standard configuration)

- Heat exchanger – connection to the network of the client via the heat exchanger

- Heat meter

- GSM module and possibility to control the system via Internet

- Sinc in boiler room

- Tool box with tools and gas burner for firing

- Installation of a window in boiler room

- Installation of gates in storage (height 1500 mm)

- Increase of chimney

- Installation of surveillance cameras

- Installation of a larger ash box

- Rotary valve before supply screw into the boiler. Obligatory, if fuel moisture is less than 30%